Surgeons rely on their tools just as much as their training when it comes to repairing the complex framework of the human body. The right equipment can make the difference between a routine recovery and a complicated one. This article explores the critical role that specialized tools play in modern medicine, particularly focusing on the needs of healthcare professionals who demand excellence. We will examine the variety of instruments available, the importance of material quality, and how companies like New Med Instruments are setting new standards for precision and reliability in operating rooms around the globe.

The Vital Role of Precision in Bone Surgery

Precision is not just a luxury in surgery; it is an absolute necessity. When dealing with the musculoskeletal system, a fraction of a millimeter can impact a patient's mobility for life. Surgeons require orthopedic instruments that act as seamless extensions of their own hands. These tools must offer tactile feedback, perfect balance, and unwavering durability. Whether a surgeon is setting a fracture or performing a delicate spinal fusion, the instrument must perform flawlessly every single time. This level of reliability ensures that the focus remains entirely on the patient and the procedure at hand, rather than on the equipment being used.

Understanding the Variety of Surgical Tools

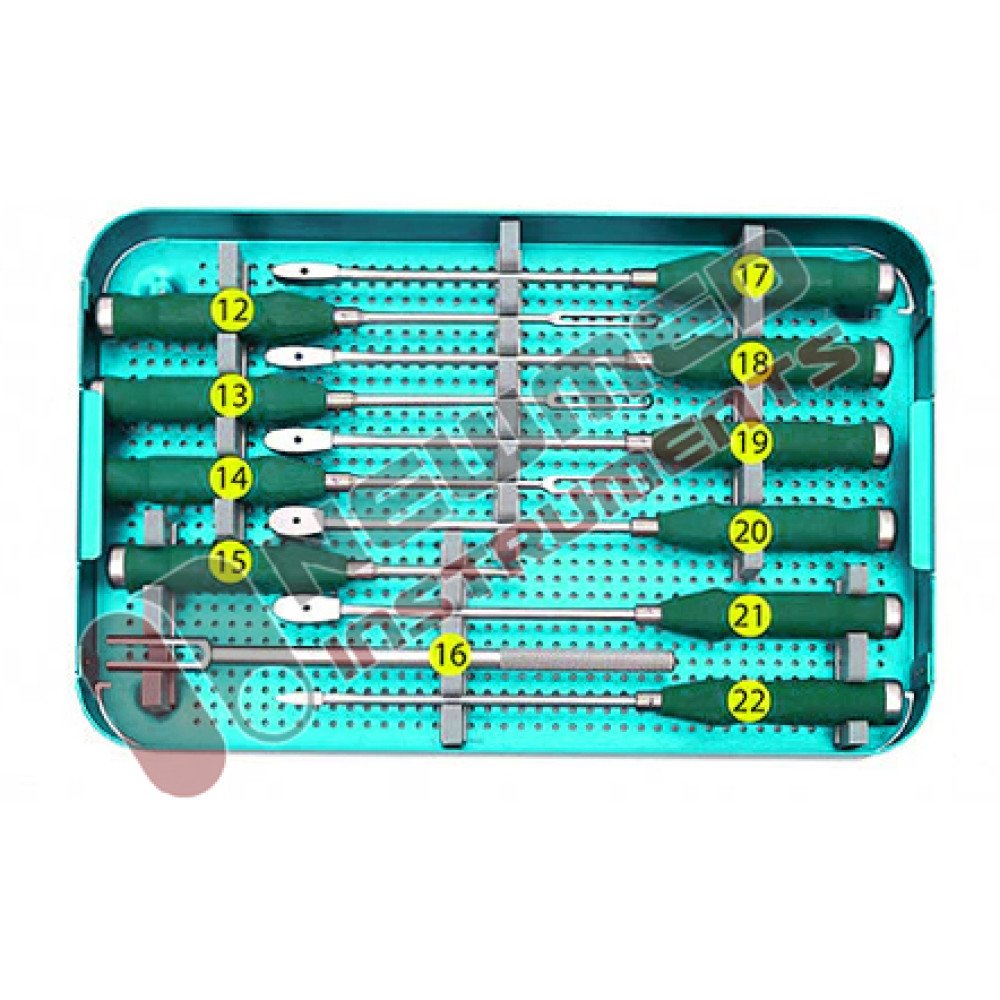

The sheer variety of tools required for musculoskeletal procedures is staggering. A standard tray might contain everything from heavy-duty bone cutters and mallets to delicate retractors and precision drills. Each instrument serves a unique purpose in the surgical workflow. For example, retractors are essential for holding back tissue to expose the surgical site without causing damage. Forceps and clamps manipulate tissues and bones with varying degrees of pressure. This diversity means that hospitals and clinics must source their inventory from trusted providers who understand the nuances of every specific tool. New Med Instruments recognizes this need and offers a comprehensive catalog designed to meet the diverse requirements of modern surgical teams.

Quality Materials Make the Difference

The materials used to manufacture surgical tools determine their longevity and safety. Stainless steel and titanium are the gold standards because they resist corrosion and can withstand repeated sterilization cycles. High-quality steel ensures that cutting edges remain sharp procedure after procedure, reducing the need for frequent replacements. When a hospital invests in superior orthopedic instruments, they are investing in patient safety. Poor quality materials can degrade, lose their edge, or even break under stress, which is an unacceptable risk in an operating room. Manufacturers committed to excellence prioritize high-grade materials to ensure every tool meets rigorous medical standards.

Innovation in Surgical Design

Surgical techniques are constantly evolving, and the tools used must evolve with them. Modern instrument design focuses on ergonomics to reduce surgeon fatigue during long procedures. A handle that fits more naturally in the hand allows for greater control and reduces the risk of slippage. New Med Instruments stays at the forefront of these innovations, ensuring that their products incorporate the latest design advancements. This commitment to innovation helps healthcare professionals perform at their best. By constantly refining the design of orthopedic instruments, manufacturers help surgeons achieve better outcomes with less physical strain.

The Importance of Reliable Sterilization

Infection control is paramount in any surgical setting. Instruments must be designed to be easily and thoroughly cleaned. Complex mechanisms or textured surfaces can sometimes harbor biological debris if not designed correctly. The best surgical tools feature smooth finishes and accessible joints that allow sterilization agents to reach every surface. This attention to detail in the manufacturing process directly contributes to lower infection rates and safer surgeries. Healthcare facilities need partners who understand that the lifecycle of an instrument includes hundreds of sterilization cycles. Durable construction ensures that these tools maintain their integrity and functionality even after years of rigorous cleaning.

Supporting Surgeons and Students Globally

The medical community is a global network of professionals dedicated to healing. From seasoned surgeons in major metropolitan hospitals to medical students learning the basics in teaching clinics, everyone needs access to reliable equipment. New Med Instruments is dedicated to serving this wide audience by providing superior service and shipping worldwide. They understand that a student practicing on a cadaver needs the same reliable feel as a surgeon operating on a living patient. This universal approach to quality helps raise the standard of care everywhere. By making high-quality orthopedic instruments accessible to a global market, they empower the next generation of healers.

Why Precision Results Matter for Patients

Ultimately, the goal of every surgery is a perfect result for the patient. A well-healed bone, a restored joint, or a corrected deformity can give a person their life back. The tools used in these procedures are the bridge between the surgeon's skill and the patient's recovery. When surgeons have confidence in their equipment, they can operate with greater certainty and efficiency. This leads to shorter surgery times, less tissue trauma, and faster recovery periods. New Med Instruments builds their reputation on this connection between tool quality and patient outcomes. Their focus on precision ensures that patients receive the best possible chance for a full recovery.

Choosing the Right Partner for Surgical Supplies

Selecting a supplier for surgical instruments is a strategic decision for any healthcare facility. It involves looking beyond just the price tag and considering the value of customer service, product reliability, and long-term partnership. A good supplier acts as a resource, helping hospitals manage their inventory and ensuring they have the right tools when they need them. New Med Instruments prides itself on superior service, ensuring that surgeons and procurement managers have a hassle-free experience. Their dedication to the field of orthopedic instruments makes them a valuable ally in the quest for medical excellence.

Conclusion

The landscape of modern surgery is defined by the tools that make it possible. High-quality instruments are fundamental to successful outcomes in musculoskeletal procedures. From the materials used to the ergonomic design, every aspect matters. New Med Instruments stands ready to support the medical community with tools that meet the highest standards of precision and durability. Healthcare professionals looking to upgrade their inventory or students seeking reliable practice tools should explore their comprehensive catalog to see how quality manufacturing can enhance their work.

Comments